About 1998 the Knights Armament Rail Interface System (RIS) became type standardized for the Special Operations Command SOPMOD rifle program. Soon after, Atlantic Research Marketing Systems (A.R.M.S.) entered the rail system fray with their series of rifle and carbine length rail systems.

The adoption of the KAC RIS and then the KAC M4 Rail Adapter System and the M5 Rail Adapter System for the U.S. Army’s M4/M16 Modular Weapon System (MWS) program solidified the future of rail systems on modern combat rifles. As a ‘stop-gap’ effort to field a similar capability, Colt developed and marketed the “Y” hand guard design.

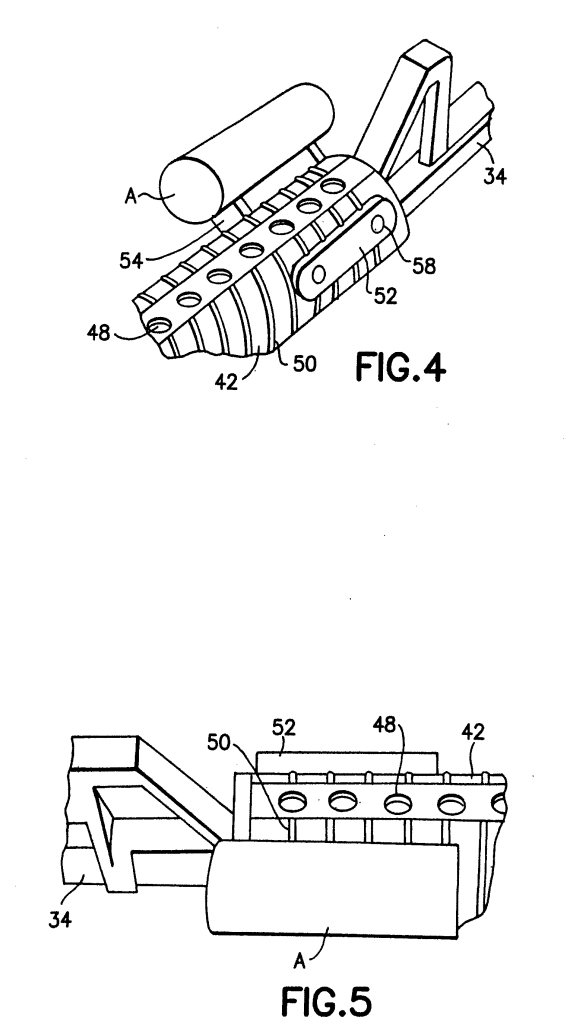

The Y-hand guard design was designed by Mr. Vincent Battaglia of Colt. The patent for the design was filed on April 25, 2005. An additional patent application was filed by Colt Defense LLC for the same design on July 16, 2008. The two patents are linked below.

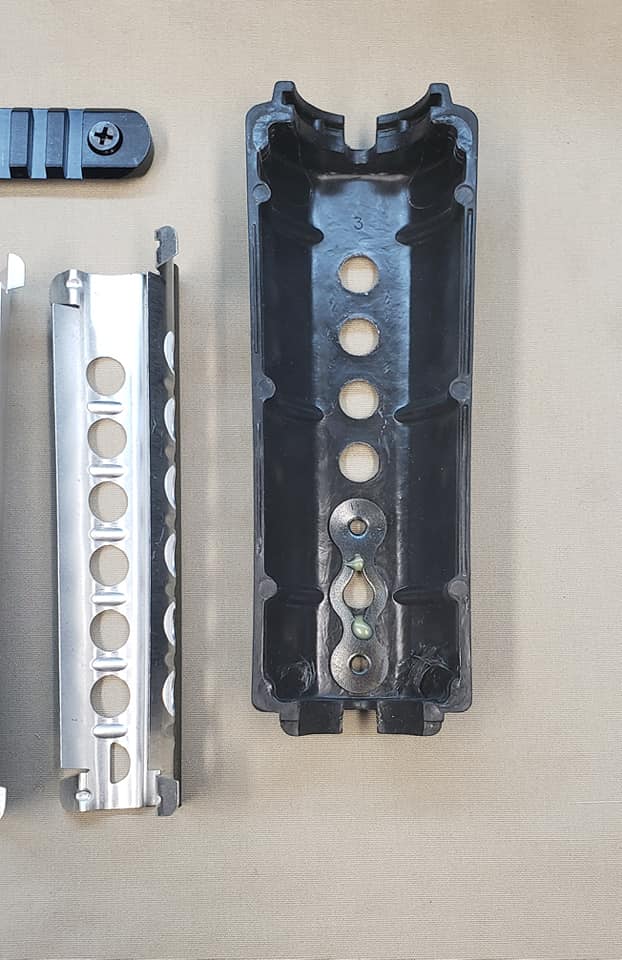

The Y-hand guard system was standard 7-hole carbine hand guards with double heat shields. Holes were drilled in the top section for the mounting of rails. Both the top and bottom rail sections screwed into retaining plates that were glued into the hand guards.

This type of hand guard was used by Tunisia and at least one other Middle East customer. The hand guard system was assigned Colt part number 98104 and was mounted on Colt R0977 (14.5″ barrel with safe, semi, auto selector).

I purchased this set from J&T Distributing for $45 about 17 April 2018

The next several images are of the Y-hand guards in use on Tunisian special forces weapons.